Bear Iron Works

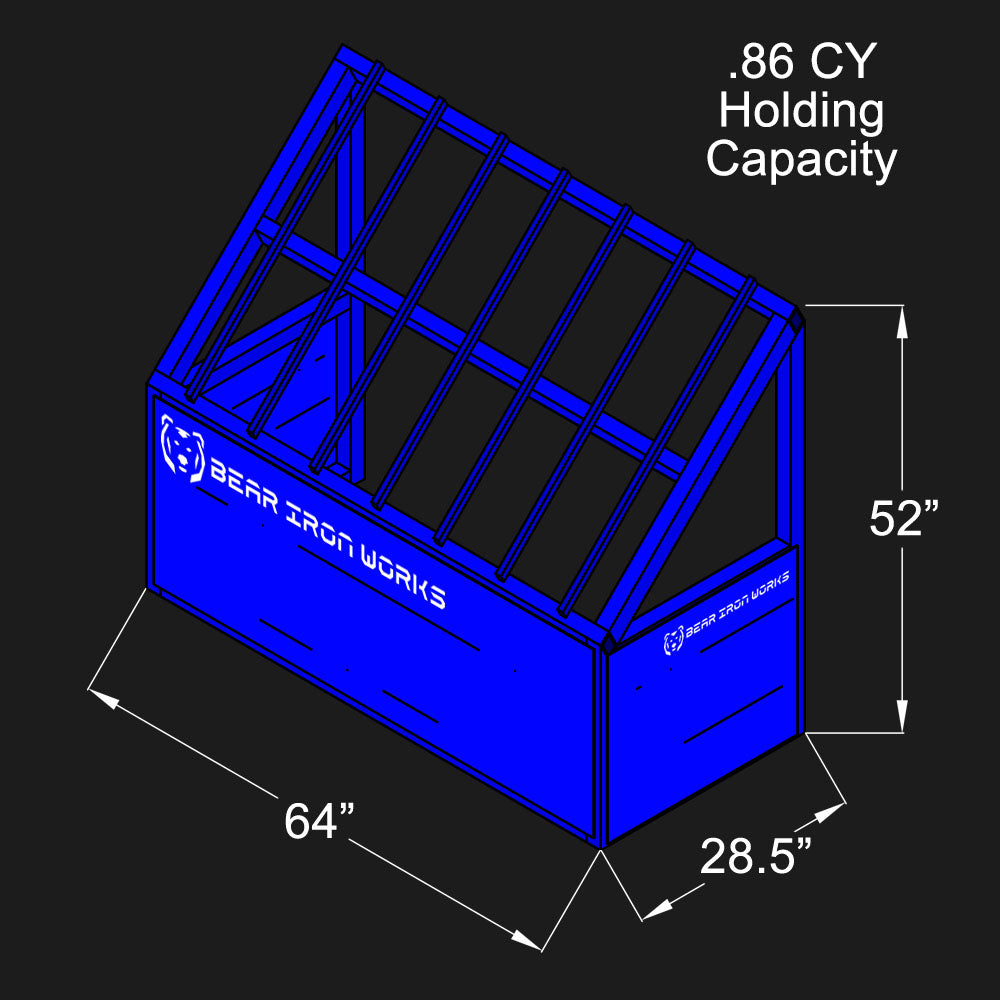

Koala Rock Screen

2 in stock

Pickup available at Bear Iron Works HQ

Usually ready in 5+ days

SHIPPING INFO

SHIPPING INFO

CUSTOMERS NEED ADEQUATE EQUIPMENT TO UNLOAD ANY PRODUCT PURCHASED!

Bear Iron Works will utilize a carrier at their discretion for the transport of the product(s). Shipping pricing to the 48 continential United States is precalculated on the bearironworks.net store. Any purchases made through bearironworks.net are only eligible for shipping to the continental 48 United States. Orders to be delivered anywhere else in the world must be made via email: info@bearironworks.net or phone: (970) 210-6152

REFUND AND RETURNS

REFUND AND RETURNS

Orders may be cancelled with 24 hours. After the 24 hour period is complete then:

ALL SALES ARE FINAL

Due to the nature of our products and the difficulty to return them, all sales are final. If there is a defect on the product in question, please reference our warranty policy here: https://www.bearironworks.net/pages/warranty

WARRANTY

WARRANTY

All of our products come with our standard warranty found here: https://www.bearironworks.net/pages/warranty

PRIVACY POLICY

PRIVACY POLICY

We need to collect certain information at the time of sale. Please read our privacy policy to understand how we use this information.

A small grizzly rock screen for small yard tractors

We call it the Koala! We are the only ones to make it. This popular rock screen has been a hit among landscapers, homeowners, and commercial property maintenance. This rock screen is meant to be used with either a small yard tractor or a ride-on skid steer. This rocks screen is great for those DIY projects!

Will your equipment work with the grizzly rock screen?

We have grizzly rock screens for sale for every size of equipment. The Koala is meant to screen soil with a skid steer. Most most equipment will be able to lift and maneuver the grizzly. The one factor that is important is your bucket width.

The Koala has an inside width dimension of 60". If your bucket is any wider than 58", we recommend using the next size up, the Cub grizzly rock screen.

How to use a grizzly rock screen

Rock screens are very easy to use. There are two key principals to understand to use a rock screen. They are how to move the rock screen and how to screen material.

How do I move a Bear Iron Works grizzly rock screen?

Using the Koala rock screen with a small tractor, you can pick up the grizzly rock screen with your bucket from the middle cross rail on the inside of the grizzly rock screen. Typically, you will want to use the top of your bucket to grab this cross rail, slowly curl your bucket outwards until your bucket cutting edge meets the rock screen or front edge. From here you should be able to lift the grizzly and move it to where you need.

You should place your grizzly rock screen near your source material, so you can make efficient cycles. You will also want to have access to both the front and back of the screen, so you can clear out the larger debris and scoop your screened soil, respectively.

How do I screen rocks with a grizzly rock screen?

Once you have positioned your rock screen in an optimal location, dig a bucket full of your source material. It is recommended to approach the grizzly from the back (tall side) when you dump your material. This will prevent rocks from rolling into your machine. When you are behind the grizzly, raise your bucket to just above the top of the grizzly. Position the cutting edge of your bucket so when you start to slowly dump your material, it will fall onto the rails of the grizzly rock screen and the material will run down the screen. The small, desired material will fall through the screen, where you can access it from the back side. The large material will run to the front of the grizzly. Repeat your cycle, until you have enough screened soil for a bucket full. You can then take your screened material to wherever you may need.

Separate rocks and other debris from soil with a grizzly rock screen

Using a grizzly rock screen as a rock separator is the most common use, but a grizzly screen can screen much more. If you have material that is filled with trash, litter, or any other unwanted debris, you can use a grizzly screen to separate that debris from your soil.

So, it's a soil cleaner?

Yes! It's a simple tool that has multiple uses. Our customers have used them for many creative uses. Municipalities in Florida have used our soil screeners to clean the beaches of trash. When combined with our removable screen, they were able to clean any debris from the sand that was larger than 1/4" That is a great way to clean things that get buried in the sand.

What else can you screen with a grizzly?

Our agriculture customers have used our screens to clean rocks from manure so they could sell a clean product to the market. We have had firewood companies screen firewood from soil. The wildest one, it was sold to a meat processing plant. If you really want to know, give us a call.

Screen topsoil with a grizzly rock screen

Our grizzly rock screens are one of few on the market that allow you to make precise topsoil. Our removable screen system allows for smaller and precise screening. Most of our competitors only sell screens that go down to 1". Our can go as small as 1/4".

Add a removable screen for variable and precise soil screening!

Not only do our removable screens allow for variation of your screened materials. They are also more precise than a grizzly alone. We utilize square wire crusher screen, the same screen used in large scale aggregate processing equipment. Since it is square, it will give you a true to size material. The removable screens range from 1/4" to 3".

Easy to change rock screen sizing with a removable screen

Our removable screens can be interchanged without leaving the seat of your equipment. You do not have to use bolts, pins, nuts, or anything else besides your machines to change the screens. Our system allows for you to change your screen size as easy as scooping dirt. Our rock screen combined with a removable screen is still half the cost of a grizzly with adjustable rails, and our is even more versatile.