At Bear Iron Works, we take pride in offering the strongest and most affordable rock screening equipment on the market. Our Grizzly rock screens are made with solid steel rails, ensuring maximum durability and longevity.

But don't be fooled by our affordable prices – our competitors often charge twice as much for their grizzly rock screens because they include unnecessary features and complex designs that drive up the cost. We believe in keeping things simple and efficient, which is why we've refined our design to create the strongest, most affordable grizzly rock screen available.

.

Our Rock Screen Design

See Mike explain how the rail design on our grizzly rock screen is different and how we believe our rails are the strongest design for a grizzly rock screen.

The rock screen rails are the most important part of a grizzly rock separator, as the rails receive the initial force from the oversized material. It is crucial for the rock screen rails to have strength to avoid deflection, but also be small enough to allow for an effective screen area.

That is why we choose solid steel over hollow tubing. Solid steel resists deflection better as it is thicker than the walls of a hollow tube. Since the hollow tubing needs a larger volume to be structural, it takes away from the effective rock screening area, which is the ratio of screen spacing to center line distance of rails. Rock screens with larger spacing will have a greater effective screening area.

For example, if you have 1-inch solid steel rails and a 3-inch spacing, your effective screening area is 3:4 (75%), meaning you need 4-inches to create a 3-inch space. A hollow tube rail system would typically require 2-inch tubing, so for a 3-inch spaced grizzly, the effective rock screening area would be 3:5 (60%), meaning you need 5-inches to create a 3-inch space. There are fewer chances for the desired material size to fall through on the hollow tube design.

A funnel effect can be created by standing the rails on ends increasing the effective screen area. However, this creates a wedge to trap rocks and clog the rock screen. It also requires expensive fabrication techniques to maintain the same weld strength to the frame.

grizzly rock screens

Change Screen Sizing

Change your rock screen sizing without leaving the seat of your machine. Add adjustability to your grizzly gravel screen with the help of a removable scalping screen! We have sizes ranging from 1/4" to 3" on all models of grizzly rock screens!

Additionally, our removable scalping screens offer precision. Since the screen is made from crusher screen, the square abrasion resistant material provides true to size screening precision when sifting soil.

grizzly rock screens

Grizzly Rock Separator Screen - Built To Last

This grizzly rock sifter was one of the first Mama Bears built. We built this one in 2017. At the time this picture was taken, it was 2 years old, and helped construct a fairly large subdivision in Gypsum, CO.

When we took the picture, we inspected the grizzly rock sifter, and there was not a single broken weld! It truly is a great display of our products’ durability. We have further revised our dirt sifter designs since then to make our grizzlies even stronger! We take pride in producing the types of rock screens that last.

grizzly rock screens

Transparent Pricing

We try to make our products as affordable as possible. That's why we don't hide our prices like our competitors. Don't waste your money on a grizzly rock screen that costs as much as a car.

Buy a BIW rock screen - it will do the same exact thing for a fraction of the price. It's also stronger!

.

Grizzly Rock Screens for Sale - Buy Now!

Cubs and Koalas ship free everywhere in the 48 United States! Mamas and Papas ship free within 1000 miles of our facility.

-

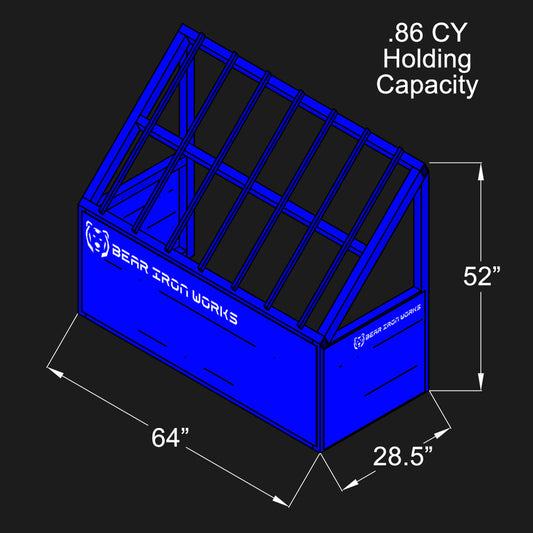

Koala Rock Screen

Vendor:Bear Iron WorksRegular price $3,400.00 USDRegular priceUnit price per -

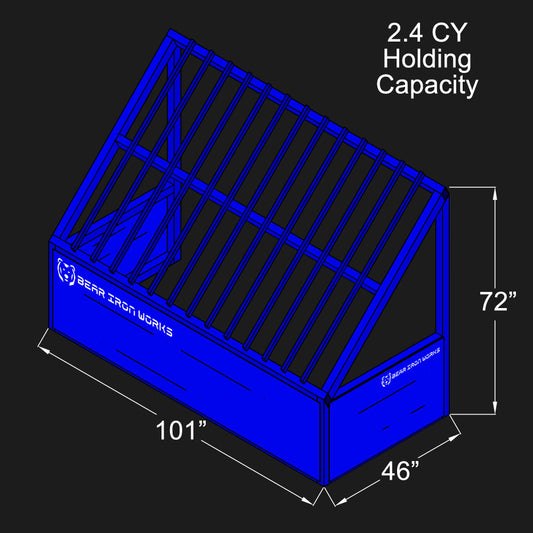

Growler Rock Screen

Vendor:Bear Iron WorksRegular price $4,800.00 USDRegular priceUnit price per -

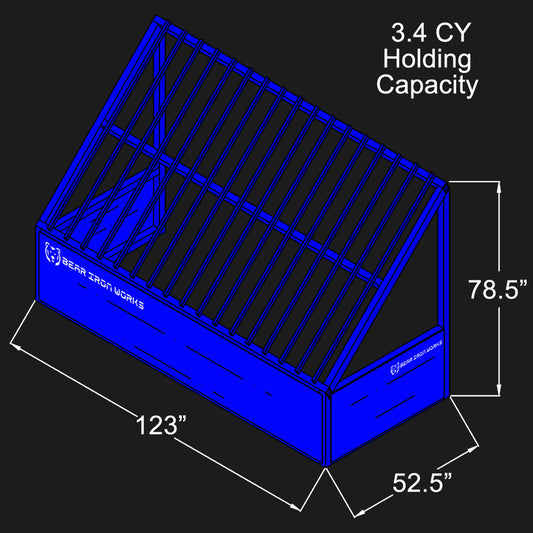

Cub Rock Screen

Vendor:Bear Iron WorksRegular price $5,100.00 USDRegular priceUnit price per -

Mama Rock Screen

Vendor:Bear Iron WorksRegular price $6,300.00 USDRegular priceUnit price per -

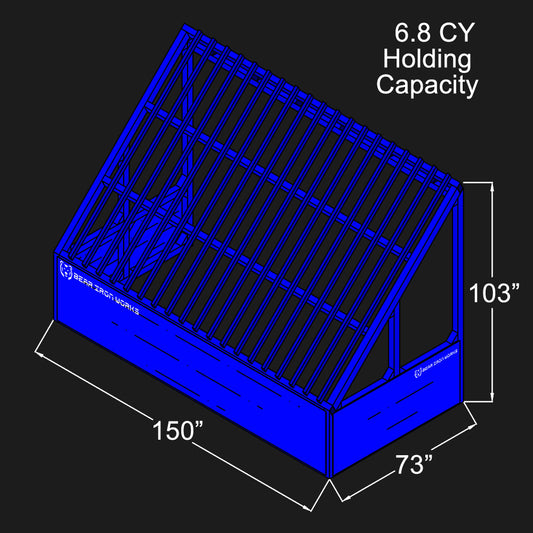

Papa Rock Screen

Vendor:Bear Iron WorksRegular price $11,600.00 USDRegular priceUnit price per